Precision cleaned hardware is susceptible to damage if not properly packaged and protected. In this blog post, we will discuss the correct methods for packaging and protecting precision cleaned hardware.

Let's get started!

Why Proper Packaging is Crucial to Protecting Precision Cleaned Hardware

Precision cleaned hardware is essential in many industries, from manufacturing to healthcare. However, this type of hardware must be free of contaminants to function properly. That's why it's so important to use proper packaging and protection when precision cleaning your hardware.

When precision cleaning hardware, it is crucial to use the proper packaging to protect it from contaminants. The type of packaging we use will depend on our precision cleaning.

We specialize in cleaning and packaging the following items:

- Gauge cleaning

- Transducer cleaning

- Components

- Valves

- Filters

- Check valves

Proper Packaging: Our Process Explained

The importance of proper packaging can't be understated. Using the proper packaging ensures that your precision cleaned hardware arrives clean and free of contaminants.

Let's look at how we ensure your products are properly protected.

Approved Coverings

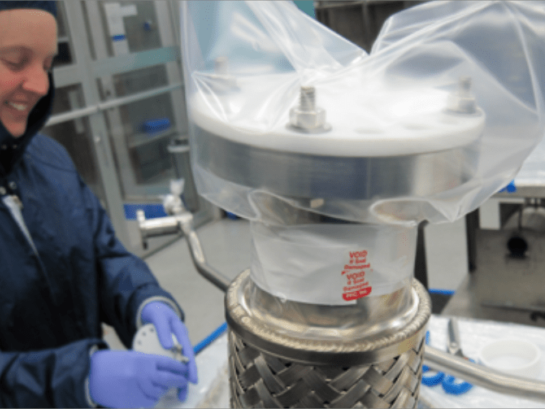

We work our way from the outside in, ensuring that each piece in the packaging process is free from contamination. As a result, we start by inspecting the coverings of each product.

We make sure that all coverings are clean and in good condition before the packaging begins. This includes looking for rips, tears, or any other damage that could allow contaminants inside.

We also check the seals on all coverings to ensure they're intact. Once we've inspected the coverings, we move on to the packaging process.

Packaging Materials

The next step is to select the proper packaging materials. Again, we take into account the type of precision cleaned hardware being packed, as well as the shipping method.

For example, if we're packaging delicate precision cleaned hardware for air shipment, we'll use different materials than we would for ground shipment. This helps to ensure that your precision cleaned hardware arrives safely and without damage.

PFC only uses clean, contaminant-free materials to cover precision cleaned hardware.

All our packaging materials go through a thorough inspection done by a QA inspector. To ensure precision cleaned hardware arrives in the same condition, it left our facility, only clean and contaminant-free materials are used to cover the hardware.

Pressure Sensitive Packaging Tape

We use pressure-sensitive packaging tape to seal all our packages. This type of tape is designed to adhere to surfaces without leaving a residue.

It's also easy to remove, so you can be sure that your precision cleaned hardware will be safely and efficiently unpacked when it arrives at its destination.

Heat Sealing

For some types of precision cleaned hardware, we use heat sealing. This is a process that involves using heat to seal the packaging.

This helps to create a tamper-proof seal that will keep your precision cleaned hardware clean and free of contaminants.

Precision Cleaned Hardware: An Overview

We also take into account what precision cleaned hardware is being packaged. Each piece of hardware is precision cleaned to remove all contaminants.

This includes both particles and chemicals. In addition, we clean our products in a sanitized environment. This prevents the introduction of contaminants during the cleaning and packaging process.

Once the precision cleaned hardware is packaged, it's ready to be shipped. We use a variety of shipping methods to get your precision cleaned products back to you.

Gauge and Other Shock Sensitive Pieces

Gauges and pressure transducers see a lot of wear and tear. Over time, they can become contaminated with particles and chemicals. Precision cleaning ensures that your gauges are free of contaminants.

This process removes all particles and chemicals from the surface of the gauge. As a result, precision cleaning helps prolong your gauge's life.

However, if the packaging after the cleaning is improper, your precision cleaned gauges could become recontaminated. That's why it's important to use the proper packaging to protect your precision cleaned hardware.

At PFC, we ensure that these pieces of hardware do not see any vacuum pulling, as they are shock sensitive. We also take into consideration their static discharge properties. This is done to protect precision cleaned hardware further.

Component Openings

Component openings often have sharp edges. However, the most important aspect of protecting component openings is to cover the parts that will contact the service media.

We ensure that all component openings are properly sealed before packaging. This helps to prevent damage and contamination during shipping.

Filters

Filters are subject to breakage as they have many fragile components. We take care to package filters in a way that will reduce the risk of breakage.

This includes using support materials and padding to protect the filter elements. We also use pressure-sensitive packaging tape to seal the filters in place.

This helps to ensure that your precision cleaned filters arrive safely and without damage.

Certification and Additional Protection

After your precision cleaned hardware is packaged, it's ready to be shipped. We use various shipping methods to get your precision cleaned products back to you.

We also offer certification and additional protection for your precision cleaned hardware. Certification ensures that your precision cleaned hardware meets our high standards for quality and cleanliness.

Additional protection helps to keep your precision cleaned hardware safe from damage during shipping. This includes using special packaging and shipping methods.

Precision Cleaning Services: Start Today

To ensure the longevity and quality of your precision cleaned hardware, it is important to explore the importance of proper packaging and protection. At PFC, we understand the importance of protecting your investment.

That’s why we offer various packaging and protection services that will keep your hardware clean and contaminant-free. Check out our website or reach out today to learn more about how we can help you protect your precision cleaned hardware.