There are more than 94 million cleanrooms that are installed across the globe. That is just in one size. There are more than 150,000 of a larger size that has been installed across the globe.

Additionally, at least 8,000 cleanrooms are expected to be put up each year. These rooms are used in various industrial, medical, and research settings and they work to limit the amount of particulate matter or dirt that could interfere with sensitive operations within the cleanroom by filtering the air and keeping it at optimal conditions.

So, what exactly is a cleanroom and why is it important for many industrial companies? We explain the answers here so keep reading.

What Exactly is a Cleanroom Environmental Control Area (ECA)?

So, what are cleanrooms? In short, they're simply spaces with controlled environmental parameters and they're designed to reduce the presence of dust or any other airborne organism, vaporized particles, and other contaminants.

The reason for this is to help maintain quality in manufacturing, research, and processes where external contaminants could affect the work being done inside the room. By filtering the air and keeping it at optimal conditions, companies can work on one or multiple projects without cross-contamination.

Controlling the air in one part of a larger cleanroom allows that part of the cleanroom to maintain a specific environment while the rest of the cleanroom can be set up for another operation. ECA is a space within a cleanroom where the air's filtered and controlled.

This air's often recirculated to reduce the amount of outside air needed. The inside air's kept at a specified temperature and humidity and may be pressurized to reduce the number of particles that enters the room.

A cleanroom environmental control area (ECA) is a space within a larger cleanroom where the air isn't only filtered but also controlled. This is an example of a static cleanroom that is entirely operable on its own without the need for any personnel. There are also more dynamic options as well which can include personnel inside the room.

A Look at A Few Capabilities

The main purpose of the room is to have it remain free of particulate contamination. The way this happens is mainly through using HEPA or ULPA filters. Cleanrooms are typically classified into two main categories or types.

They are either going to be ventilated or you could call them non-unidirectional. The second type's categorized as the opposite, a unidirectional flow cleanroom. Each room will also be categorized by a class or federal standard and will have an ISO equivalent.

For example, the FED STD-209E will often range from Class 1 to Class 100,000. Each room will also have a set of requirements associated with it. From the efficiency of the filter and its coverage to how often the air changes and even the type of ceiling that comes with the unit.

What Are the Benefits of a Cleanroom and Why Should Industrial Companies Have One?

There are a variety of benefits to having a Cleanroom Environmental Control Area. Let's take a closer look at some of the primary benefits.

Reduction of Risk of Contamination

Contaminants in the air can cause harm to expensive or delicate equipment. A cleanroom protects equipment from dust, bacteria, and other harmful substances.

Protection of Equipment

Small particles can easily get into small holes or gaps within machines. This is one of the main causes of machine component obstructions. Over time accumulated debris could block vents or other portions of the machine.

This can also cost companies money if replacements are needed. By filtering and removing these particles from the air you could alleviate this.

Reduction of Allergy Irritation

While this may not always be a concern. Those who work in cleanrooms sometimes suffer from fewer allergies. This is because there are fewer substances in the air, which are often the main irritants for allergies.

This means that cleanrooms can be beneficial for employees who suffer from allergies if you won't be using a static room.

Improved Accuracy

In industries such as medical, research, and semiconductor manufacturing, cleanrooms can improve the accuracy of certain things. Some of these things could b a variety of instruments and processes, resulting in less waste and better outcomes.

Faster Processes

Some processes, such as testing and analysis, can get done faster when using a cleanroom. This is because there is less interference from outside contaminants.

Increased Efficiency

Cleanrooms can result in more efficient use of resources, such as electricity and water.

How Do They Make a Difference?

Cleanrooms help to limit unneeded exposure. These rooms aren't always sterile, but they follow a certain set of standards. These standards help to keep industrial processes safe and simple to work within.

Most cleanrooms use a ventilation system for this, but some use a system known as air showers. Air showers are a specific type of filtration system. Air enters the system through a showerhead at a high velocity, where it's filtered before recirculation to the rest of the cleanroom.

By reducing particle buildup, air showers also increase efficiency, and they are often less expensive than conventional ventilation systems.

Types of ECA

Industrial operations may have multiple projects or segments of operations going. Whether it's live manufacturing, testing, or general development, the type of cleanroom you use can be made to match what you do. There are three main types of clean rooms.

- Soft

- Rigid

- Hard

These types don't just refer to the structure or texture of the room. They also match up with the different cleanroom classifications. For example, soft wall rooms are quite lightweight.

They can usually match up to most standards, but not all. In comparison. a hard wall room can comply with any cleanroom standard or classification and they are modular as well. Let's take ISO 5 and 7 as examples.

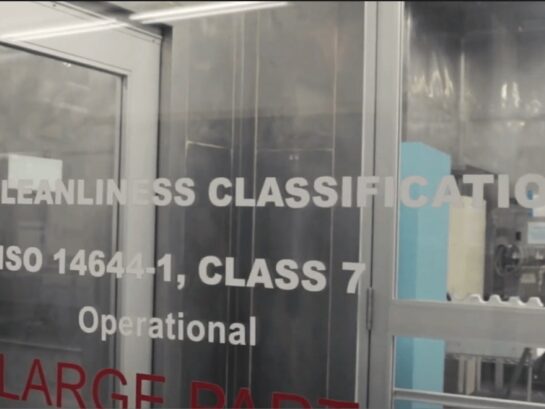

ISO 7 Cleanroom

The ISO 7 cleanroom is a hard-wall room. This room is a class 10,000 and what that means is that it maintains a level of air filtration of up to 10,000 particles for every cubic foot.

ISO 5 Cleanroom

An ISO 5 which is the class of the room, requires a higher filtration level than most. This particular type of clean room is an example of one that would have unidirectional airflow. It will often take more air changes per hour than an ISO 7 cleanroom would.

Tackle Complex Projects

Cleanroom Environmental Control Area can save companies time and money. They can also lessen the need to repeat processes. If you need precision cleaning, cryogenic and cold shock testing, or even field and mobile cleaning, you should work with Precision Fabricating & Cleaning.

To find out more about our unique processes, get in touch with our team today.