Filters play a critical role in maintaining system efficiency, product quality, and safety by removing contaminants from fluids and gases.

Category: PFC

Hydrostatic vs. Pneumatic Testing: Which Proof Testing Method is Right for Your Application?

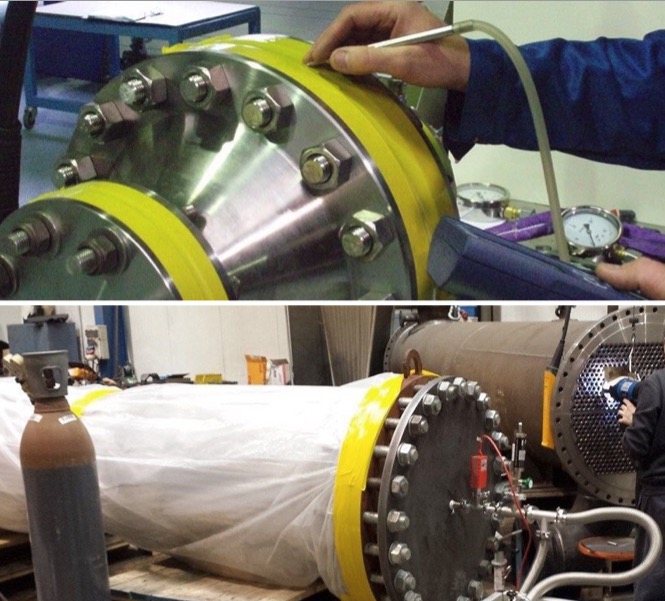

Proof testing is a crucial process in various industries to ensure the safety, reliability, and integrity of components, pipelines, and pressure vessels.

Understanding Pressure Gauge Accuracy: A Guide to Choosing the Right Level

Pressure gauges are ubiquitous in a wide range of industrial and commercial applications, from chemical processing and pharmaceutical manufacturing to hydraulic systems and HVAC controls.

Sniffing, Spraying, and Bagging: Exploring the Techniques of Helium Mass Spectrometer Leak Testing

In manufacturing and quality control, ensuring product integrity is crucial. Even the smallest leaks can compromise performance, safety, and reliability.

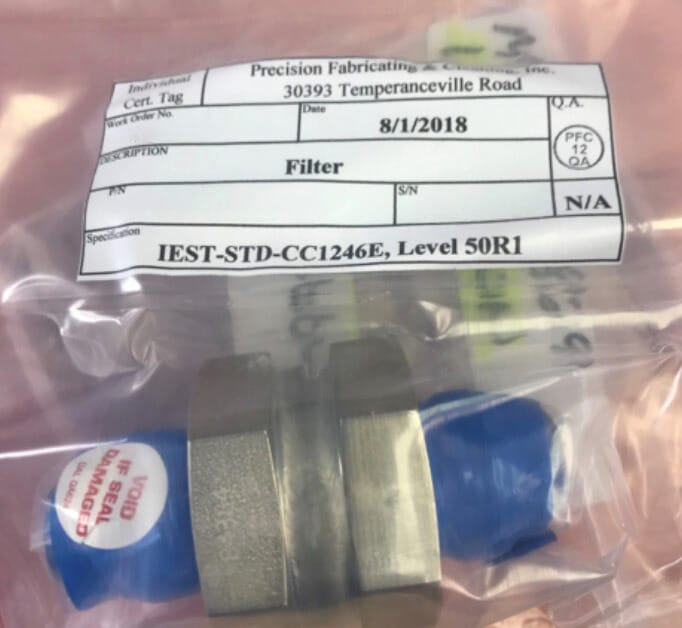

Protecting Your Investment: The Importance of Proper Packaging for Precision Cleaned Parts

Precision cleaning hardware is not sufficient – preserving post-cleanliness is equally critical.

Why Particulate and NVR Testing Matters for Precision Cleaned Components

Rather than gamble on visual-only verification, particulate measurement and NVR testing provides definitive proof that precision cleaned components meet rigorous cleanliness standards

The Advantages of Outsourced Precision Cleaning & Testing vs. In-House (Super Guide)

Let’s dive into the specifics of precision cleaning & testing, and why handling such a complex process in-house rarely makes sense.

Shining a Light on Cleanliness: Understanding Visual Inspection and Visibly Clean Standards

Visual inspection is one of the most critical steps in any quality control process.

Depowdering: Why Precision Cleaning is Crucial for Additive Manufactured Parts

Discover the importance of precision cleaning in additive manufacturing, focusing on depowdering to boost component performance and longevity.

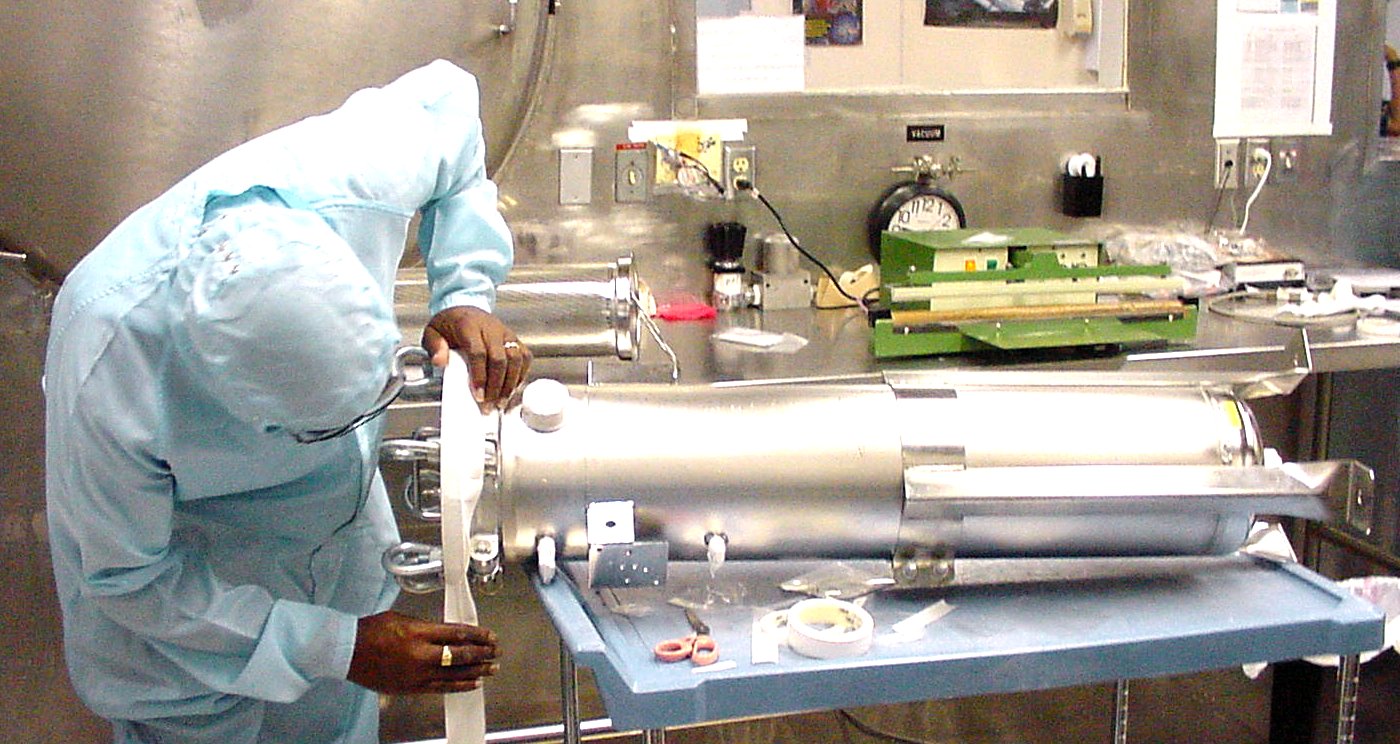

An Overview of Cleanroom Standards and Procedures: Benefits of a Pristine Environment

In industries like manufacturing or aerospace, few factors are more important than access to controlled environments.