When it comes to specialized industrial components and sensitive systems used in critical industries like aerospace, optics, and semiconductors, precision cleaning & testing is an absolute necessity. The microscopic residues and particulates left behind if cleaning isn't done properly can completely hamper functionality and quality.

However, establishing rigorous precision cleaning in-house requires massive investments in equipment, facilities, training and expertise. This is why outsourcing precision cleaning to dedicated specialists has become the preferred choice.

In this blog post, we'll dive into the specifics of precision cleaning, and why handling such a complex process in-house may not always make sense.

We compare factors like costs, expertise requirements, risk management, quality assurance, and more to outline the advantages outsourced precision cleaning partners have over in-house operations.

While the importance of high purity cleaning can't be overstated for companies dealing with highly complex components, trying to handle it in-house comes with too many challenges that can jeopardize output quality.

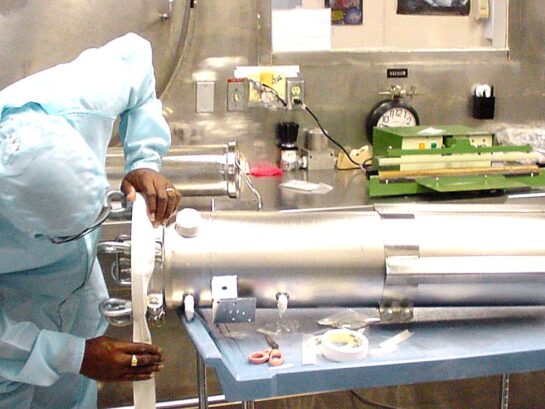

Partnering with seasoned precision cleaning & testing experts like Precision Fabricating & Cleaning who invest heavily in state-of-the-art processes, cleanrooms and certifications, is emerging as the way to go for most enterprises today.

Table of Contents

Expertise and Specialization—Let the Experts Focus on What They Know Best

One of the biggest benefits of outsourced precision cleaning & testing providers is their teams of seasoned specialists dedicated to these meticulous processes on a daily basis. Trying to handle such delicate procedures with cross-trained personnel or through general manufacturing staff brings massive risks of errors and contamination.

- Outsourced precision cleaning providers have highly experienced professionals where this is their core job function every single day. They possess both the hands-on expertise of daily precision cleaning work and integrated institutional knowledge of proven techniques, common failure points, advanced protocols and more. Their teams live and breathe high purity cleaning, unlike any cross-trained resources you may temporarily allocate at your own facilities.

- Outsourced precision cleaning providers have large proprietary databases of procedures, component-specific cleaning instructions, compliance requirements and other critical knowledge gained through years of experience catering to regulated sectors with sensitive systems.

- Staff can tap the learnings from thousands of prior jobs to determine optimal processes for current jobs. Assurance of product and process compatibilities also stem from established knowledge banks on component interactions, chemical responses, optimal sequences, environmental condition maintenance and much more.

By leveraging these deeply experienced teams dedicated solely to precision cleaning & testing, you ensure both humans and systems with the best knowledge are handling your most sensitive assets. Their expertise stemming from years of specialization creates immense value.

Ongoing Consultation for Continuous Improvements

The benefits of tapping into precision cleaning & testing expertise extend well beyond one-time project execution. Leading outsourced providers also offer huge consultative advantages helping to enhance your internal asset handling and maintenance practices.

- For one, they serve as great educative resources to improve organizational knowledge around precision cleaning needs. Through sustained engagements, they can proactively share best practices around handling techniques, storage protocols, maintenance scheduling and more to bolster the lifecycle management of your sensitive components. Workers who interact with these assets daily gain tremendous knowledge around contamination avoidance, cleaning requirements, emergency procedures, etc.

- Additionally, seasoned precision cleaning & testing partners lend their design consultation skills to help customers identify potential problematic areas in existing systems/components that may need future attention. By assessing known problems across equipment variants in your industry, they can pinpoint likely candidates for enhancements to reduce future cleaning and servicing needs. This allows you to proactively mitigate issues before they arise and require urgent solutions.

- They also make recommendations to engineer physical aspects of your components and systems to minimize contamination risks and enable easier cleaning where needed. Guidance around optimal material finishes, and other facets stems from extensive projects across client portfolios over the years.

The breadth of institutional knowledge high purity cleaning providers hold makes them invaluable long-term partners to tap frequently, not just one-off service providers.

Compliance with Critical Industry Standards and Certifications

When dealing with highly specialized industrial components and systems, compliance with various regulatory, quality and compliance standards is paramount but exceedingly difficult to achieve consistently in-house. This is another key area where precision cleaning & testing specialists excel.

Leading outsourced precision cleaning providers invest heavily in various accredited quality certifications like:

- ISO 9001

- ISO 14644

- AS9100D

As well as specific environmental health standards. Maintaining these stringent certifications requires institutionalized processes for protocol development, equipment management, staff training, detailed reporting, traceability mechanisms and much more.

The costs for both achieving and sustaining these credentials can be lofty for any individual Enterprise. Precision cleaning & testing providers effectively mobilize these investments across entire client portfolios to make the unit economics work. They are also constantly updating protocols and investing in new tech capabilities to adhere to the latest industry safety, quality and compliance rule changes.

By leveraging these compliant supply chain partners, client enterprises fulfill critical certification needs for their high purity-based components and systems with much lower overhead. They also mitigate massive risks associated with defective outputs reaching customers due to compliance failures on complex regulatory and performance qualifications.

For highly regulated industries, outsourcing precision cleaning & testing to appropriately certified specialists brings immense value over the steep investments and risks of managing this in-house. The expertise and infrastructure needed to maintain continually evolving industry compliance standards is challenging to recreate internally at scale.

Cost Efficiency—Only Pay for What You Need

Establishing in-house precision cleaning & testing capabilities requires massive capital investments in specialized equipment, custom facilities, extensive training and much more. The costs to build and sustain these assets reliably at scale are enormously high.

Outsourced precision cleaning providers have already made these investments to serve wide client portfolios. The volumes they handle allow for economies of scale unviable for individual enterprises. These partners optimize equipment utilization, facility designs, supply logistics and staffing much more efficiently across clients.

Enterprises only pay for the specific services needed rather than inflating budgets for full-time specialized infrastructure and labor. Variable demand is easily managed. Surges in cleaning needs faced internally would mean overextending difficult-to-adjust in-house capacities.

Outsourced precision cleaning providers readily scale services to match needs thanks to flexible infrastructure and staff. They also continually integrate the latest tech advancements which individual players cannot cost-justify frequently.

Outsourced Precision Cleaning & Testing Focuses Efforts on Core Strengths

For enterprises specializing in building highly complex components and systems, establishing in-house high purity cleaning eats into limited focus that should be directed towards advancing core design and engineering strengths.

- Trying to recreate specialized precision cleaning & testing expertise internally ends up diverting key leaders and technical talent towards non-core operations. Extensive resources get channeled into equipment procurement, facility design, cleaning technique research and staffing recruitment/development functions peripheral to most product-driven organizations.

- Existing engineering teams get continually pulled into addressing cleaning-related issues given their component intimacy and troubleshooting experience. This hampers their capacity to engage more deeply in iterative R&D and long-term production improvements. Their problem-solving bandwidth gets constrained despite the immense value their specialized skills could bring to advancing core products.

- Outsourced precision cleaning & testing stops the leakage of scarce technical resources towards non-differentiating activities. It allows enterprises to redirect their top talents’ energies squarely into the design, testing and enhancement of complex equipment they uniquely excel at.

When paired with dedicated high purity cleaning experts, product development teams can increase their velocities and outputs without dilutive activities. The specialized division of labor results in higher-quality core offerings thanks to greater internal bandwidth. Engineering productivity and end-user value enhancement accelerate with outsourcing.

Bundling Complementary Services for Added Convenience

Leading precision cleaning specialists like PFC offer far more than just stand-alone component cleansing. Top outsourced partners provide a range of complementary services that can be conveniently bundled around cleaning for added value.

For one, providers offer ancillary functions like component testing, surface treatments, light assembly work and custom packaging along with primary cleaning processes. Combining these services simplifies logistics and coordination efforts for enterprises. Components needing high purity cleaning likely also require adjacent preparatory or finishing touches best addressed by the same specialized provider.

These partner shops also offer component refurbishment and refinishing offerings as part of their service catalog. This allows for extension of life and redeployment of components like valves, vessels, cylinders and other capital equipment that may need precision cleaning & testing before being reset. Instead of needing to coordinate across multiple vendors and transport sensitive assets between shops, integrated services are available in one spot.

Consolidating high purity cleaning and adjacent downstream processes through one outsourced partner greatly simplifies planning and drives efficiency gains for enterprises. Components stay put after initial cleaning for finishing processes instead of incurring risks, delays and costs through additional transportation and orchestration. The breadth of capabilities allows customized bundling across the value chain.

Streamlined Logistics and Supply Chain Management

Outsourced precision cleaning partners greatly simplify downstream supply chain logistics for sensitive components thanks to their integrated service capabilities. For one, providers offer direct drop shipping of finished components to end-customers after completing all cleaning and ancillary processes in-house.

This alleviates enterprises from establishing piecemeal transportation and warehousing across various stages of post-production finishing. It also reduces risks of contaminant exposure from additional material hand-offs. Components stay securely within precision shop ecosystems through the entirety of processes before personalized delivery.

These shops effectively become one-stop intermediaries handling the complete spectrum of high purity cleaning, testing, supplementary services, custom packaging and forwarding to final destinations as needed. Everything gets bundled into a streamlined engagement model through order finalization. Component traceability and chain of custody documentation also improve thanks to systemized handoffs to the customer site.

By leveraging outsourced precision cleaning & testing partners as the supply chain bridge from production to deployment, enterprises achieve massive gains in logistical simplicity, cost efficiency, and risk reduction for sensitive components.

Leveraging Cutting-Edge Capabilities and Flexible Scale

Precision cleaning is a highly technology-driven process where newer techniques, equipment and chemistries can greatly impact cleaning quality and efficiency. Top outsourced partners invest heavily in continually evaluating and integrating the latest advancements to these mission-critical processes.

These players closely track emerging methods from industries like semiconductor manufacturing and aerospace. They implement pilot projects to test applicability for components from other sectors that may benefit from these technology migrations. Staying atop these evolving best practices would prove very difficult for enterprises to replicate themselves without dedicated research staff.

Outsourced precision cleaning providers also offer immense scalability advantages over in-house operations. Demand surges are easily managed due to flexible staffing and equipment resources spread across clients. Temporary capacity expansion to handle monthly or seasonal order spike requires no CapEx from enterprises themselves.

Outsourced precision cleaning providers augment capabilities rapidly through operational leverage vs capital-laden in-house increases.

Conversely, sudden order volume drops can be absorbed through shared partner infrastructure without leaving enterprises over-committed to underutilized internal assets. The pooled resources and flexible capacity of outsourced partners prove extremely valuable for enterprises facing variable needs.

Transferring Risks to Specialized Partners

Instituting internal high purity cleaning & testing capabilities comes with significant quality control and environmental health & safety risks that prove highly complex and costly to manage over time. However, partnering with outsourced specialists enables transfer of these substantial, non-core risks to dedicated stewards.

Outsourced precision cleaning providers assume full ownership over ensuring stringent quality checks, component traceability documentation, cleaning efficacy validation protocols and overall output reliability. Enterprises mitigate direct risks of internal compliance failures or defective precision work impacting customer deliverables and downstream production quality.

These outsourced providers also take on handling of:

- Harsh chemicals

- Contaminated wastewater disposal

- Specialized equipment maintenance intrinsically tied to high purity cleaning processes

By relinquishing these significant environmental and personnel risks to expert partners, enterprises realize massive operational risk savings.

Rather than building skills internally to govern these precarious activities adjacent to core competencies, working with experienced outsourced precision cleaning specialists provides superior risk control. Regulatory non-compliance, personnel accidents, and asset integrity failures become third-party risks driving greater organizational resilience.

Unwavering Quality Standards and Assurances

Achieving meticulous quality control around high purity cleaning activities is non-negotiable but highly challenging without dedicated governance infrastructure. Outsourced precision cleaning specialists operate under the strictest certifications and institutionalized procedures focused solely on output excellence.

These providers adhere to acclaimed standards like AS9100D and ISO 9001:2015 requiring exhaustive protocol development, equipment management, staff training, compliance reporting, and continuous improvement mechanisms. Cleanliness validation testing and component traceability documentation follow meticulous guidelines with precisely defined pass/fail criteria.

Outsourced precision cleaning providers invest heavily in world-class cleanrooms, integrated management systems for streamlined activity logging, chain of custody records, advanced portal access for customers and other facets critical for quality assurance. The combination of certified quality frameworks, cutting-edge tools and robust documentation infrastructure ensures every job meets the highest standards.

For individual enterprises trying to replicate similar quality rigors internally, the costs and complexities often overwhelm non-specialist teams fairly quickly. Partnering with dedicated experts who live and breathe these protocols proves the most prudent means to achieving excellent output quality confidently and consistently. It also provides helpful consultative support to further strengthen internal component traceability and handling practices.

Massive Time Savings on Specialized Staffing

Building an in-house high purity cleaning process requires immense time investments into recruiting scarce talent with specialized capabilities, intensive operator training, designing efficient staff workflows, and extensive management oversight of complex procedures. Maintaining minimal contingent staff permanently for intermittent needs also proves highly time-inefficient.

Outsourced precision cleaning providers leverage extensive teams where cleaning work is the sole focus. The operators are already fully trained, effective protocols are institutionalized, efficient schedules are established, and managers provide dedicated oversight. Customers avoid all time-intensive activities associated with building this specialized capability internally.

The time savings extend to not needing specialized HR staff to continually source and evaluate talent in tight labor markets. Demand forecasting, capacity modeling, workload balancing, and other optimization efforts also require dedicated internal resources without outsourcing.

Partners take on all specialized staffing activities as their core business function, freeing customers to invest their limited time into advancing differentiating capabilities like production technologies, R&D pipelines and next-gen product designs instead. The time and distraction savings from avoiding specialized recruitment and workforce development for non-core precision cleaning & testing lets enterprises maximize human capital productivity.

Sustainability and Compliance Practices

High purity cleaning activities utilize various harsh chemicals and produce hazardous wastewater requiring stringent disposal protocols to limit environmental impact. Managing these intrinsically risky processes internally can prove highly complex for individual enterprises from sustainability and regulatory compliance perspectives.

However, experienced providers' invest extensively in institutionalizing environmentally friendly practices including:

- Responsible chemical storage and handling policies

- Advanced filtration mechanisms to allow chemical recycling

- Equipment innovations to minimize solution contamination

- Onsite treatment of water discharge streams before regulated disposal

- Component recycling initiatives and reuse process design

- Renewable energy and emission reduction infrastructure

- Paperless workflow documentation

These memberships in sustainability consortiums to continuously improve recycling rates, carbon footprint and achievement of ambitious environmental targets.

By leveraging outsourced partners, enterprises can fulfill their own eco-goals through third parties deeply committed to planet-friendly practices long before most companies could justify such investments. Especially for medium enterprises with tighter budgets, outsourcing to specialists with verifiable sustainability infrastructures offers major green advantages. It also provides helpful environmental compliance knowledge transfer to improve in-house asset handling as well.

In Conclusion: Partner with a Precision Cleaning & Testing Specialist like Precision Fabricating & Cleaning

As we've covered, establishing in-house high purity cleaning is a massive challenge across operational, financial and risk management dimensions for enterprises focused on engineering and production of complex components. The specialized expertise, equipment investments, facilities, compliance protocols and other prerequisites impose severe burdens best avoided by partnering with dedicated cleaning experts.

Outsourced providers like Precision Fabricating & Cleaning specialize in precision cleaning clea& testing work day in and day out. They've made all the specialized infrastructure and skills investments needed to provide superior cleaning & testing quality and output assurance at scale across clients. PFC’s teams have decades of experience and continually push the boundaries of technical excellence to meet the most delicate precision requirements.

PFC offers comprehensive solutions covering precision cleaning, supplemental finishing processes like testing and coatings, bundled logistics right to customer doors, and environmentally friendly practices. PFC's ISO and AS certifications validate stringent quality adherence and commitment to driving the industry forward responsibly.

As an organization focused solely on supporting enterprises through best-in-class precision cleaning & testing solutions, PFC's ready to eliminate those burdens for your organization.

Partnering with Precision Fabricating & Cleaning allows enterprises to focus energies on advancing core solutions while they handle the meticulous cleaning & testing complexities. This symbiosis provides the foundation for long-term quality, productivity, and speed advantages previously unattainable.