When it comes to precision cleaning, aqueous-based degreasing is popular alongside traditional solvent methods. But what exactly is degreasing?

At its core, degreasing is a critical process that removes oils, greases, dirt, and contaminants from system hardware surfaces before any precision cleaning or passivation can take place. The industry primarily relies on two approaches: solvent-based and aqueous-based degreasing solutions, each with distinct advantages for specific applications.

While both methods aim to achieve the same end goal—contaminant-free surfaces—they work through different mechanisms and excel under different circumstances. Understanding when to deploy solvent degreasers versus aqueous-based solutions can significantly impact cleaning effectiveness, processing time, and even environmental compliance.

In this article, we'll examine the key differences between these degreasing methods and provide guidance on selecting the optimal approach for your specific cleaning challenges.

Table of Contents

Key Takeaways

- Degreasing is a critical first step in any precision cleaning process, removing oils, greases, and contaminants that would interfere with subsequent treatments like passivation.

- Solvent-based degreasing excels at removing oils and lubricants from complex geometries and moisture-sensitive components, particularly when using ultrasonic energy to reach tight spaces.

- Aqueous-based degreasing systems offer superior performance for mixed contamination scenarios and are generally more environmentally friendly, though they require proper water treatment considerations.

- Temperature plays a crucial role in aqueous-based cleaning effectiveness, with most solutions operating optimally between 140-170°F to accelerate chemical reactions and improve contaminant removal.

- Quality verification through water break testing provides objective evidence of proper degreasing - a clean surface shows continuous water sheeting without beading or breaks in the film.

- Material compatibility should guide your degreasing method selection, as certain metals and alloys may react poorly to either solvent or aqueous-based approaches.

- PFC offers comprehensive expertise in both degreasing uses, ensuring your precision components receive the optimal cleaning approach based on material, contamination type, and end-use requirements.

Understanding Solvent-Based Degreasing

Solvent-based degreasing operates on a fundamental chemical principle: "like dissolves like." This approach uses organic compounds to dissolve and remove organic contaminants such as oils, greases, and other hydrocarbon-based substances from metal surfaces. Solvent degreasers work by breaking down the molecular bonds between the contaminant and the surface, allowing the dissolved material to be carried away from the part being cleaned.

The industry employs a variety of specialized solvents, each with particular strengths. Isopropyl Alcohol (IPA) serves as a versatile option for lighter oils and fingerprint removal. For tougher applications, more specialized solvents like Cyclohexane tackle stubborn hydrocarbon residues, while HFE 7100 excels at removing fluorocarbon lubricants commonly found in aerospace applications. Other options include Vertrel MCA, Solstice PF, and Coventry 12830, each formulated for specific contaminant types and material compatibility profiles.

At the chemical level, these solvents function by reducing the surface tension between the contaminant and the substrate. The solvent molecules surround and encapsulate the contaminant molecules, lifting them from the surface through dissolution rather than mechanical action. This makes solvent degreasing particularly effective for reaching into small crevices and complex geometries where mechanical cleaning might be ineffective.

Application methods vary based on part complexity and contamination level. Simple immersion allows solvents to penetrate tight spaces and complex geometries. Vapor degreasing uses heated solvent vapors that condense on cooler parts, providing fresh solvent contact continuously. For particularly stubborn contamination, ultrasonic degreasing combines solvent chemistry with high-frequency sound waves (typically 40 kHz) to create microscopic cavitation bubbles that implode against surfaces, enhancing cleaning power and reaching into blind holes and internal passages.

Understanding Aqueous-Based Degreasing

Aqueous-based degreasing represents a water-centered approach to contamination removal that uses specialized cleaners combined with water to break down and remove both organic and inorganic contaminants. Unlike solvent methods that dissolve contaminants, aqueous-based cleaners work through a combination of chemical processes: detergency (the ability to wet surfaces and emulsify oils), saponification (converting oils into soaps), and suspension (keeping contaminants from redepositing on cleaned surfaces).

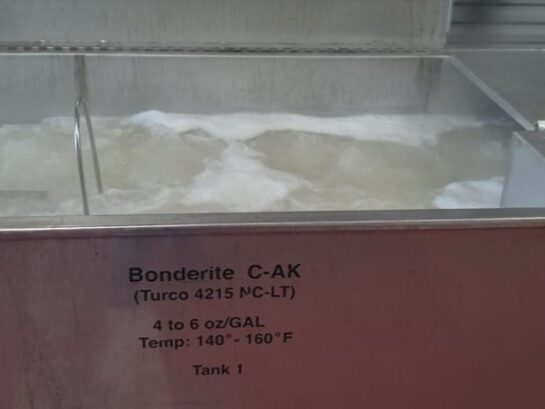

Several formulations dominate the industrial cleaning landscape. Turco 4215 NCLT, a powdered alkaline cleaner, is widely used at concentrations of 4-6 oz/gal for precision applications. Naval Oxygen Cleaner (NOC), developed for oxygen-sensitive systems, offers high cleaning power with low residue potential. Other effective options include Brulin 815GD, Daraclean 282, and Amway nonionic L.O.C, each formulated for specific contamination challenges and material compatibility requirements.

Temperature plays a crucial role in aqueous-based degreasing effectiveness. Most aqueous-based cleaners operate optimally between 140-170°F (60-77°C), as higher temperatures accelerate chemical reactions, reduce surface tension, and increase contaminant solubility. Concentration is equally important – too dilute and the solution loses cleaning power, too concentrated and it may leave residues or damage sensitive materials. Each cleaner has specific recommended concentrations (for example, Turco 4215 NCLT at 4-6 oz/gal) that balance cleaning power with material compatibility.

Application methods for aqueous-based degreasing include immersion tanks with agitation systems, spray systems for larger components, and ultrasonic tanks that combine chemical action with acoustic cavitation for enhanced cleaning of complex parts. Many facilities employ multi-stage systems that progress from initial gross cleaning to progressively cleaner solutions, followed by thorough rinsing stages. For parts with complex geometries, specialized fixtures ensure complete solution contact and proper drainage, while temperature-controlled tanks maintain optimal cleaning conditions throughout the process.

Comparative Analysis

When selecting between solvent and aqueous-based degreasing methods, several factors must be considered to ensure optimal cleaning results. Each approach demonstrates different strengths when confronting specific contaminants. Solvent methods excel at removing oils, greases, and waxes, particularly when dealing with water-sensitive components. In contrast, aqueous-based degreasing shows superior performance against particulates, inorganic soils, and water-soluble contaminants, making it the preferred choice for mixed contamination scenarios.

Environmental impact increasingly drives degreasing method selection

Traditional chlorinated solvents face regulatory restrictions due to ozone depletion and air quality concerns. Modern solvents like HFE 7100 offer improved environmental profiles but still require careful handling. Aqueous-based degreasing methods generally present lower environmental risks and reduced VOC emissions, though they require water treatment considerations to manage effluent.

Cost comparisons reveal nuanced trade-offs

Solvent uses typically demand higher initial investment but use less chemistry per cycle. Aqueous-based degreasing often features lower upfront equipment costs but requires heating energy, water consumption, and potentially higher chemical usage. Long-term operational expenses frequently favor aqueous-based uses, especially when factoring in regulatory compliance costs associated with solvent handling.

Processing time and labor requirements vary significantly

Solvent degreasing typically delivers faster cycle times—sometimes just minutes for light contamination. Aqueous-based degreasing generally requires longer processing (15-30 minutes) but often offers greater throughput capacity for batch processing operations. Labor requirements tend to be higher for aqueous-based uses due to more complex equipment maintenance and solution monitoring needs.

Safety considerations present another critical distinction

Solvent uses require ventilation, fire safety measures, and personal protective equipment due to inhalation risks and flammability concerns. Aqueous-based degreasing solutions eliminate many flammability issues but introduce other safety considerations like slip hazards and, in the case of highly alkaline cleaners, chemical burn risks. Modern aqueous-based uses with lower-concentration, safer chemistry have significantly reduced these concerns while maintaining effective cleaning performance.

When to Choose Solvent Degreasing

Solvent degreasing represents the optimal choice for several specific applications where its unique properties provide distinct advantages. Precision electronic components, with their sensitivity to moisture and tight tolerances, typically benefit from solvent cleaning approaches. Similarly, assembled mechanisms containing multiple materials that might be damaged by water exposure are ideal candidates for solvent degreasing.

The contaminant profile often dictates selecting solvent methods. Heavy oils, waxes, and petroleum-based greases dissolve readily in appropriate solvents. Solvent degreasers particularly excel at removing:

- Fluorocarbon lubricants (Krytox, Braycote, Brayco)

- Silicone-based greases and oils

- Adhesive residues

- Flux residues from electronics

- Heavy hydrocarbon-based lubricants

Material compatibility represents another critical consideration favoring solvents. Water-reactive metals like magnesium, certain aluminum alloys, and some specialized steels can experience corrosion or surface degradation with aqueous-based cleaning. Additionally, porous materials that might trap water – creating potential for downstream corrosion – often require solvent approaches.

A prime case example showcasing solvent degreasing's advantages involves fluorocarbon lubricant removal from B-nuts and swivel fittings in aerospace applications. These precision components feature complex geometries with threads and internal passages where fluorocarbon lubricants like Krytox are used during assembly. The cleaning protocol typically involves:

- Pre-cleaning with HFE 7100-dampened cloths to remove bulk contamination

- Ultrasonic cleaning in HFE 7100 at 40 kHz for 60+ seconds

- Visual inspection for residual lubricant

- Additional processing if needed until all visible evidence of lubricant is removed

This approach leverages the solvent's ability to dissolve fluorocarbon lubricants while using ultrasonic energy to penetrate into tight spaces between threads and component interfaces – places where aqueous-based uses might struggle to reach effectively. The rapid evaporation of the solvent also eliminates drying concerns in these precision components.

When to Choose Aqueous-Based Degreasing

Aqueous-based degreasing methods shine in numerous industrial applications where their unique capabilities provide optimal cleaning results. Large-scale manufacturing components, heavy industrial equipment, and parts with significant surface contamination benefit from the mechanical and chemical action aqueous-based uses provide. Facilities processing high volumes of parts with moderate to heavy contamination typically find aqueous cleaning more economical and effective for their production requirements.

Aqueous cleaners excel at removing a wide spectrum of contaminants, particularly:

- Mixed contaminants (combinations of oils, particulates, and water-soluble soils)

- Particulate matter and metal fines

- Shop soils and fingerprints

- Water-soluble cutting fluids and coolants

- Polar contaminants that resist solvent dissolution

- Inorganic soils like salts and metal oxides

From a material compatibility perspective, aqueous-based uses perform exceptionally well with most stainless steels, carbon steels, copper alloys, and many aluminum alloys when properly inhibited. Modern aqueous formulations with appropriate corrosion inhibitors have expanded the range of compatible materials significantly, though care must still be taken with materials susceptible to flash rusting during the drying phase.

A representative case example highlighting aqueous degreasing advantages involves cleaning large industrial components with heavy oil contamination and embedded particulates. In a typical process:

- Components first undergo preliminary cleaning using a Hotsy pressure washer with heated deionized water to remove gross contamination

- Parts are then immersed in a heated tank (140-160°F) containing Turco 4215 NCLT at 4-6 oz/gal concentration for 15-30 minutes

- Agitation or ultrasonic energy enhances cleaning action

- Parts receive thorough rinsing until achieving neutral pH (6.0-8.0)

- The water break test confirms cleanliness by verifying continuous water sheeting without beading

- Components are dried using filtered nitrogen

This process effectively removes multiple contaminant layers while the heated alkaline solution saponifies oils, suspends particulates, and prevents redeposition on freshly cleaned surfaces – demonstrating why aqueous methods remain the preferred approach for heavy industrial cleaning applications.

Best Practices for Quality Assurance

Regardless of which degreasing method you select, implementing robust quality assurance procedures ensures consistent cleaning results. The water break test stands as the industry standard for verifying surface cleanliness. This test involves rinsing the cleaned part with deionized water and observing how water flows across the surface. A properly degreased surface allows water to form a continuous, unbroken sheet. The appearance of water beading, droplets, or film discontinuity indicates residual oils or contaminants requiring additional cleaning.

Visual inspection plays a complementary role in quality verification. Trained inspectors should examine parts under appropriate lighting conditions, sometimes using magnification for critical surfaces. For complex geometries, borescopes allow inspection of internal passages. Establishing clear acceptance criteria is essential—inspectors should know exactly what constitutes a passing or failing condition, with documentation that includes reference photos of acceptable and unacceptable results.

Comprehensive process documentation forms the backbone of quality control. This includes:

- Detailed cleaning procedures with specific parameters

- Records of solution concentrations, temperatures, and pH levels

- Process timing and equipment settings

- Traceability of parts through the cleaning process

- Staff training records and competency verification

When troubleshooting common issues, a systematic approach saves time and resources. For water breaks or failed inspections, first verify solution chemistry and concentrations before examining mechanical factors like insufficient agitation or inadequate rinsing. Temperature control problems frequently cause cleaning irregularities. For solvent uses, contaminated solutions or inadequate drying commonly cause issues, while in aqueous systems, rinse water quality and solution maintenance are typical trouble areas.

Conclusion

Choosing between solvent and aqueous-based degreasing ultimately depends on your specific application requirements, contamination types, material compatibility, and production volume. Solvent-based uses offer advantages for precision components, moisture-sensitive materials, and specialized contaminants like fluorocarbon lubricants. Aqueous-based methods excel with mixed contamination, particulates, and high-volume industrial applications where environmental considerations are paramount.

The most successful precision cleaning operations recognize that these methods often complement rather than compete with each other. Many facilities maintain capabilities for both approaches, selecting the optimal method based on part requirements rather than defaulting to a one-size-fits-all solution.

At Precision Fabricating & Cleaning (PFC), we've developed expertise in both degreasing methodologies through decades of hands-on experience with critical applications across aerospace, medical, semiconductor, and defense industries. Our comprehensive facilities feature both state-of-the-art aqueous-based cleaning methods and specialized solvent degreasing equipment, allowing us to tailor our approach to your specific requirements.

We understand that proper degreasing is not merely a cleaning step but a critical foundation for subsequent processes like passivation, coating, or assembly. Our documented procedures, quality control systems, and highly trained technicians ensure consistent, verifiable results that meet even the most demanding industry specifications.

Contact PFC Today

Let PFC become your trusted outsourced precision cleaning partner. Our team will analyze your specific requirements and recommend the optimal degreasing approach for your components.

Contact PFC today to discuss how our precision cleaning expertise can support your goals, eliminate quality issues, and streamline your processes.